Site Navigation

Oilfield expertise at your desktop

Condensate banking in gas wells

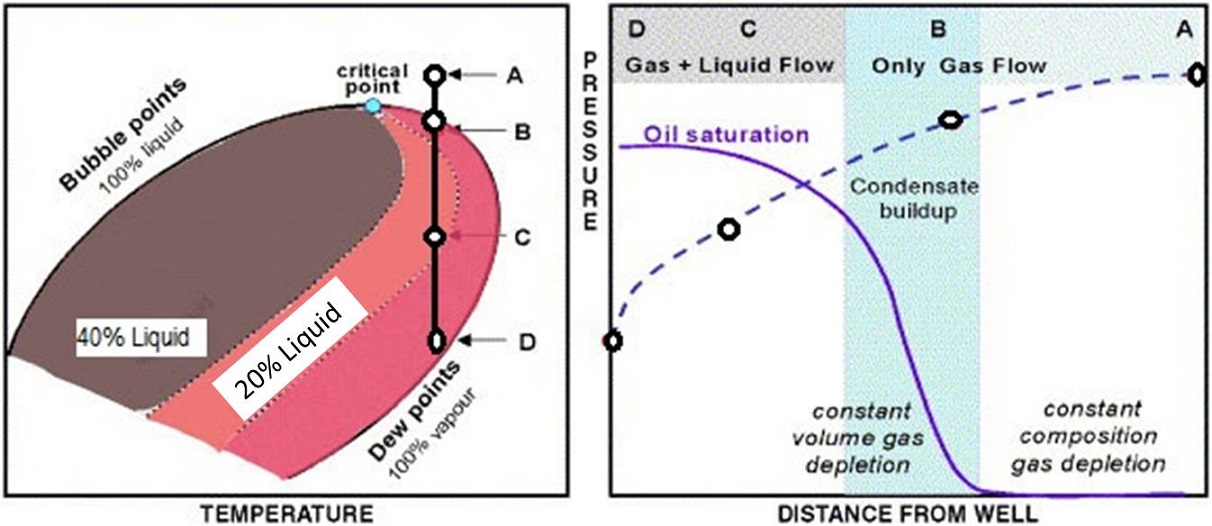

Condensate banking is a phenomenon which happens in producing gas wells when bottom hole pressure goes below dew point pressure. Fall of bottom hole pressure below dew point pressure results into condensate dropping out of the fluid and getting accumulated around the wellbore, this significantly reduces the gas permeability and hence reduces gas production.

There are two major reasons for condensate banking as given below:

- Lowering of reservoir pressure as a result of Pressure Depletion during production

- Lowering of pressure at separators as compared to reservoir pressure.

One major challenge faced by reservoir and production engineers is to determine if condensate banking is happening in the wellbore, we should always keep an eye on pointers towards condensate banking. If below indicators are observed, we should look towards suggested methods for reducing condensate banking. Some of the pointers of condensate banking are given below:

- Sudden decline in productivity.

- Having gas condensate reservoir pressure close to dew point.

- Indications of condensate bank from well test

Above pointers does not provide confirmation of presence of condensate banking as there are numerous other things happening in well-bore and reservoir which can result into above indications. As for indications from well test, affects of condensate banking in well test might be masked due to well-bore storage or complexities arising due to velocity dependent relative permeability effects.

There are several methods which are suggested to reduce condensate banking, given as below:

- Gas injection: Maintenance of reservoir pressure above dew point can easily be accomplished by dry gas injection. Further gas injection also re-vaporizes the condensate dropped in well-bore. For gas injection purpose apart from dry gas, several other gasses have also been tried namely nitrogen, Carbon dioxide (CO2) and pure methane. Each of the above mentioned gasses are having their own advantages and disadvantages, for example Nitrogen is low cost, clean and non-corrosive but is not as effective as compared to carbon dioxide.

- Huff-n-Puff method: This method reduces the dew point of fluid resulting into re-evaporation of condensate. It’s a two step process, in first step CO2 is injected in the same well used for production and then well is shut down to allow CO2 time to interact with fluid in reservoir and wellbore. This results into lowering of dew point. In second step well is opened up to produce gas. This method is more useful when condensate drop is more near the well-bore.

- Reducing capillary pressure: Reduction in capillary pressure can lead to condensate getting trapped inside the reservoir. Solvents such as alcohol can reduce capillary pressure by reducing interfacial tension.

- Hydraulic fracturing: Hydraulic fracturing increases the contact area of wellbore with reservoir and hence reduces the reservoir drawdown. Reduction in reservoir drawdown delays the reservoir pressure reduction to dew point level and hence delays the condensate banking.

- Wettability alteration: Changing the wettability of reservoir to gas wet or intermediate gas wet results into increased mobility of condensate and hence prevents condensate banking. There are various types of surfactants available in market to achieve wettability alteration.

Condensate banking is well known phenomenon which may affect gas producing wells in their lifetime. There are various methods suggested above to handle condensate banking. Each of the method is having its own pros and cons, it’s very important to choose methods which fits production strategy technically and in economic way. Carbon dioxide / Huff-n-Puff method are short term solution to condensate banking. Capillary pressure reduction and alteration in wettability only helps when condensate deposition is near well bore. Gas injection is a good method of handling condensate banking but it consumes large amount of gas and finally hydraulic fracturing is an expensive process.