Site Navigation

Oilfield expertise at your desktop

Hydraulic Fracturing

Hydraulic fracturing has been used in the oil and natural gas industry for the last 75+ years, booming for the last 10+ years, producing hundreds of trillion cubic feet of natural gas and billions barrels of oil using horizontal wells completions and multistage hydraulic fracturing, producing from mili-darcy to micro-darcy to even nano-darcy formations.

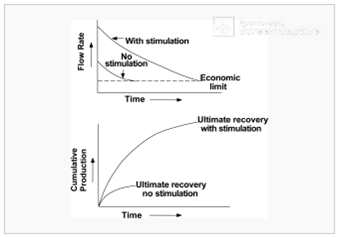

For any reservoir, Darcy law gives a quick estimation of the productivity (Qi) of a reservoir from a well angle by determining the flow through a permeable media, considering a 1-D, homogeneous reservoir with single phase of fluid having constant fluid viscosity. If we calculate the P.I. (Productivity index) using Darcy law and constant flowing bottom hole pressure (Pf), for these tight and shale reservoirs, most of the reservoirs below a mili-darcy, with no natural fractures existing in-situ, will not qualify for economic development. Even, few would not even produce anything without the help of artificial lift.Now imagine, If there were no hydraulic fracturing technology, those reservoirs would have been holding the enormous amount of hydrocarbons without contributing to the world’s energy requirements.Below curves show how the well production rates and cumulative production changes with hydraulic fracturing (stimulation)

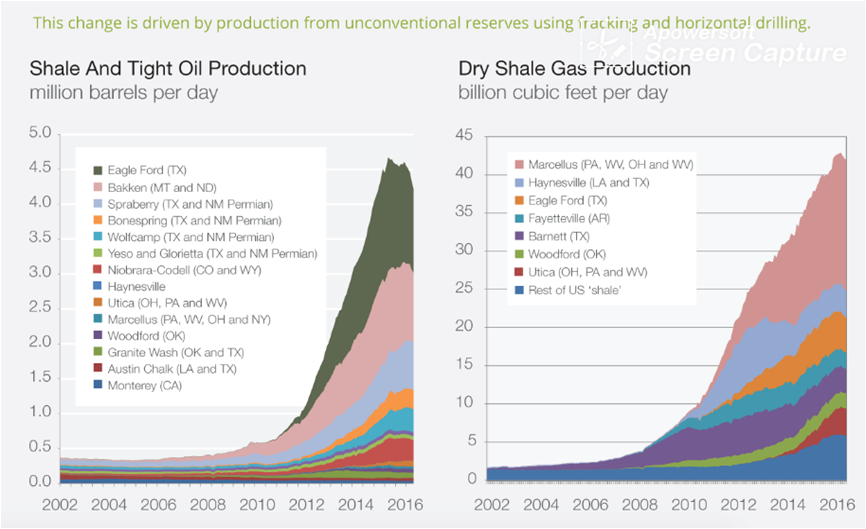

Another graph from EIA shows the mammoth impact of hydraulic fracturing on hydrocarbon production.

What is hydraulic fracturing and how does that help in higher production rates?

- Hydraulic fracturing occurs when the injection pressure is increased above the rock parting pressure.It does not change the permeability of the given formation. It creates permeable channels for the reservoir fluids to flow-in from matrix to wellbore, hence aiding for improved effective permeability through fractures permeability.

- There are two stages in a Frac job, Pad stage and Slurry stage. In Pad stage, only fluid is injected to breakdown the formation. If there is no support to keep the formation open, the fractures will close as soon as the pressure is released, so in slurry stage, fracturing fluid is mixed with proppant and then pumped in the formation above the rock parting pressure. This keeps the formation open even after the pressure is released since proppant acts like pillars.

- There are mainly two types of hydraulic fracturing jobs, e.g. slick-water fracturing and cross-linked fracturing with various gelling agents, friction reducers, cross-linked adjusters, breakers, scale inhibitors, corrosion inhibitors, oxygen scavengers, etc. to aid in efficient hydraulic fracturing job.

- There are different types of proppant with varied strengths and pressure ratings (100 mesh, 20/40, 30/50, ceramic etc.).

- There are three orthogonal, compressive and non-homogeneous stresses within the formation. The principal stress direction is very important as it controls the fracturing geometry, extension and direction of the fracture.

- Fracture geometry includes Frac width, length and height. This is also known as S.R.V (Stimulated Rock Volume). The bigger is the SRV, the higher initial rates are expected in a similar formation. Fracturing height is generally independent of fracture length and is governed by stress contract in vertical plane.

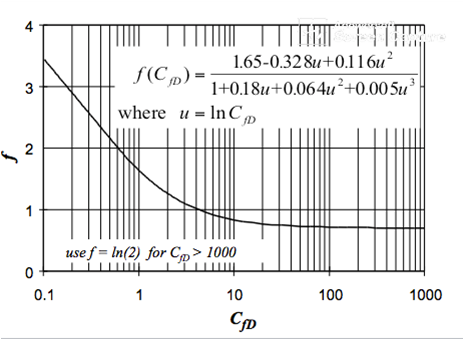

- Productivity of the fractured wells is dependent on fluid flow from matrix to fracture and from fracture to wellbore. Fluid flow from matrix to fracture is governed by fracture geometry whereas from fracture to wellbore is governed by fracture permeability. This improvement in productivity is classified as F.O.I (Fold of increase) and the below curve represents the fold of increase with dimensional less fracture conductivity.

Author of this article has detailed knowledge of hydraulic fracturing ,feel free to comment or write to us at support@oilfieldknowledge.com to discuss your challenges.